Particularly in small frames you need to be very careful with space and weight, as well as your cable management to keep things tidy and well protected. A way to make cabling a bit simpler I’m experimenting with consists in getting rid of some of the ESCs cables.

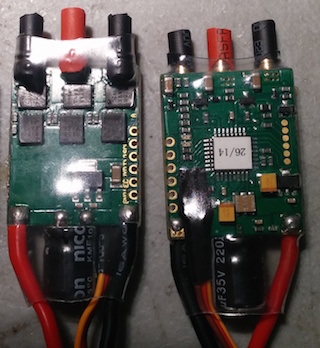

Standard Afro 20A ESCs

While these 20A ESCs are small and lightweight, having the motor female connectors sticking out restricts my choices for managing cable, specially if your motors come with longer leads. In this case, replacing the leads with bare connectors make things simpler for me.

I started by stripping the transparent heat shrink covering the ESC body. You have to be very careful so as to not harm the electronics below it. Be aware that the heat shrinking is much more resilient than it appears, so take your time.

Once the material has been removed, the body of the ESC will be exposed. There you’ll see the solder joints of the three wires that go towards your brushless motor. I simply desoldered them and removed the cable assemblies, cleaning the soldering pads with my soldering iron (for which I long ago replaced the factory tips with solid copper wire, but that’s for another day).

For each of the now naked ESCs, I took three female plugs and pre tinned them. Then carefully placed them on top of the solder pads, heated and applied solder. The very blurry result can be seen below.

Afro 20A ESCs with Connectors soldered

After this is done, I used 5mm polyolefin heat shrink tubbing to cover each individual connector. This required trimming the end of the heat shrink to cover the solder joint as much as possible. After completing this task, I used transparent heat shrink to cover and protect the whole thing.

Afro 20A ESCs Finished

I like the result because it allows me to better route the cables and keep all connections in the main body of the frame.